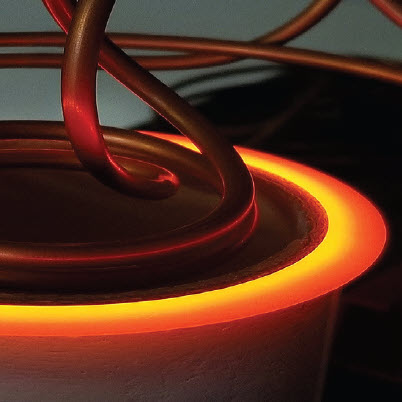

EKOHEAT® 2 with Advanced Internal Monitoring™

The Most Advanced Induction Heating System

Power To 50 kW

Operation From 5 kHz To 40 kHz

World-Class Induction Heating Systems

We’ve engineered our new EKOHEAT 2 product line to better solve your process heating challenges with an innovative, industry-leading internal control and power delivery system. From the evolution of our exclusive VPA Technology™, our enhancements boost your process accuracy, reduce your system cooling requirements, and support your work with a new control panel and suite of diagnostics and guides.

Get our Brochure

In our free 8-page brochure you’ll find an in-depth description of the features and benefits of EKOHEAT 2 with Advanced Internal Monitoring - the world’s most advanced induction heating system.

Overview of Advanced Internal Monitoring

- Closely checks and reports on key internal power supply component temperatures within the simplified cooling circuit.

- Is available in an array of configurations to serve many industrial process heating applications.

- Provides a high frequency solution for small parts or a low frequency solution for large parts.

- Offers true, high-resolution RF power control and takes full advantage of Silicon Carbide (SiC) technology, which thrives under higher operating temperatures.

- Incorporates state-of-the-art processors.

- Power supply placement up to 30 m (100 ft) from the workhead.

- Sub-second to continuous cycle times

- Remote operation or logging with RS485 port

- Comes with a large color touchscreen display.

Digital Advantages

By applying the latest semiconductor technologies, the control and monitoring of output voltage, power and resonant frequency are digitized, improving your process efficiencies and responsiveness.

EKOHEAT 2 is designed to meet the most challenging process heating applications. In our free 8-page brochure you’ll find an in-depth description of the features and benefits of EKOHEAT 2 with Advanced Internal Monitoring - the world’s most advanced induction heating system.

Get our BrochureFeatures and Benefits

Preventative Maintenance

EKOHEAT 2 is equipped to analyze internal system temperatures and pressure, enabling preventive steps.

Increased Reliability

Using an innovative design architecture, EKOHEAT 2 has 30% fewer internal plumbing connections than previous designs, therefore 30% less chance for leaks.

Dedicated Processing Power

State-of-the-art processors, dedicated to tuning the frequency of the coil for optimum performance even under heavy loads, and to executive operations such as IoT, Industry 4.0 data collection, control, and monitoring.

Large Color Touchscreen Displays

An HTML-based user interface allows the interface to appear on remote devices that have wired ethernet connections to the same Local Area Network the generator is on.

More Features and Benefits

Analog Monitoring Capability

EKOHEAT 2 offers four configurable analog outputs.

Remote Monitoring and Data Collection

are available using an external PC connected to the power supply. This provides the benefits of cloud connectivity without the security risk of a direct internet connection to the generator. The cloud connection is firewall-friendly and secure.

Customer Communication Capability

EKOHEAT 2 is compatible with RS485, Modbus RTU and Modbus TCP for native Ethernet communication.

RS485 and Modbus RTU are compatible with our previous induction model (EKOHEAT with VPA Technology). This allows for seamless integration of new power supplies into existing installations.

Modbus TCP brings the advantages of Modbus into the realm of Ethernet. Network gateways can also be used to easily convert Modbus TCP into virtually any other protocol.

Get our Brochure

AMBRELL CORPORATION

1655 Lyell Avenue

Rochester, NY 14606

United States

F: +1 585 889 4030

AMBRELL B.V.

Holtersweg 1

7556 BS Hengelo

The Netherlands

AMBRELL Ltd.

Unit 6, Space Business Centre

Tewkesbury Road

Cheltenham, GLOS, GL51 9FL

United Kingdom

F: +31 546 788 154