Objective

To heat lead or lead-free solder preforms for various circuit board soldering applications

End Product

printed circuit boards

Equipment

Ambrell 2.0 kW induction heating system, equipped with a remote workhead containing two 0.66μF capacitors for a total of 1.32 μF

An induction heating coil, designed and developed specifically for this application.

Materials

Upper and lower circuit boards, small and large lead or lead free preforms.

Temperature

< 700 ºF (371ºC) depending on the preform used

Frequency

Three turn coil 364 kHz Small two turn coil 400 kHz Large two turn coil 350 kHz

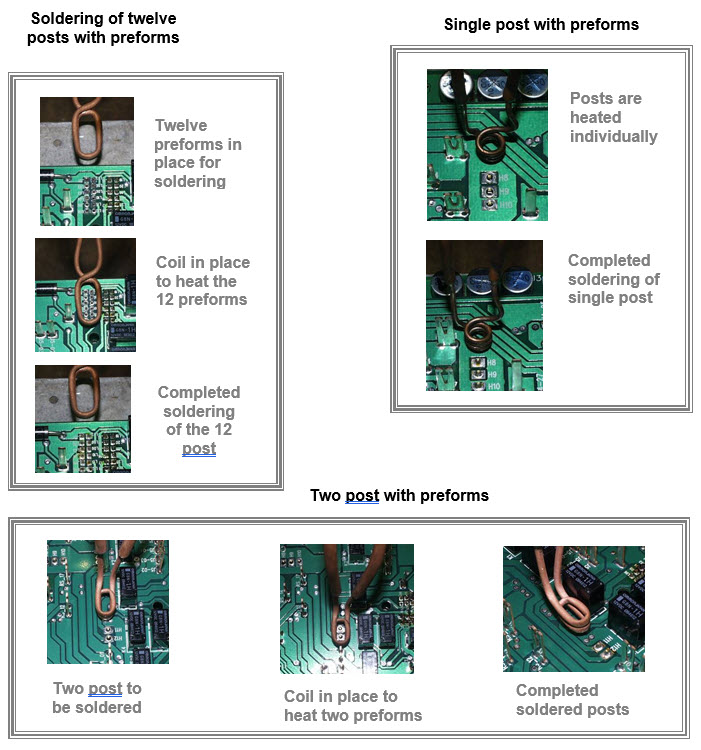

Testing

Three individual coils are used to heat the various locations on the circuit board depending upon if the location is a single application or a group application. The time varies from 1.8 to 7.5 seconds depending upon location. In production the heat stations and coils are moved into position over the post for automation purposes. Either lead or lead free solder preforms are used. The process time on the lead free solder is slightly longer.

Benefits

Induction heating provides:

-

Hands-free heating that involves no operator skill for manufacturing, lends itself well to automation.

-

Solder controlled by preforms, no excess left on board.

-

Good solder flow without over heating the board and damaging adjacent circuits and components.

Image

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000