Note: Soldering of satellite antennas

Objective:

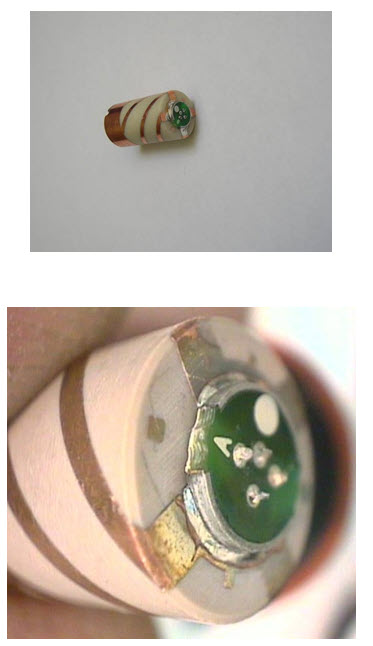

Soldering steel onto GPS body for phone antenna

End Product:

phone antenna

Equipment:

Ambrell 2 kW induction heating system, equipped with a remote workhead containing two .33μF capacitors (for a total of .66μF). Two coils (one for each stage of process) designed and developed specifically for this application. The first stage uses a two-turn solenoid coil with a 15mm (0.6 in) ID and the second stage uses a plate coil, 25 mm (1 in.) dia. with a 6mm (0.24 in.) hole.

Materials:

Thin copper foil 0.3mm (0.01 in) thick Ceramic body 12mm (0.47 in.) long x 7mm (0.28 in.) wide

Temperature:

200 °C (392Ă° F)

Frequency:

371 kHz

Testing:

Stage 1: A two-turn solenoid coil is used to heat the top end of a GPS antenna. Solder paste is used to solder the walking stick loop to the copper foil. Stage 2: A plate coil is used to heat the bottom part of the GPS to solder a top hat to the copper foil and the bottom part of the walking stick.

Benefits:

-

increased production rate due to speed of heating

-

higher quality vs. a soldering iron due to precision and repeatability

-

cost savings due to reduced scrap and higher quality production

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000