Note: Soldering fabric to kovar tip assembly

Objective:

To solder fabric to a Kovar tip assembly

End Product:

kovar tip

Equipment:

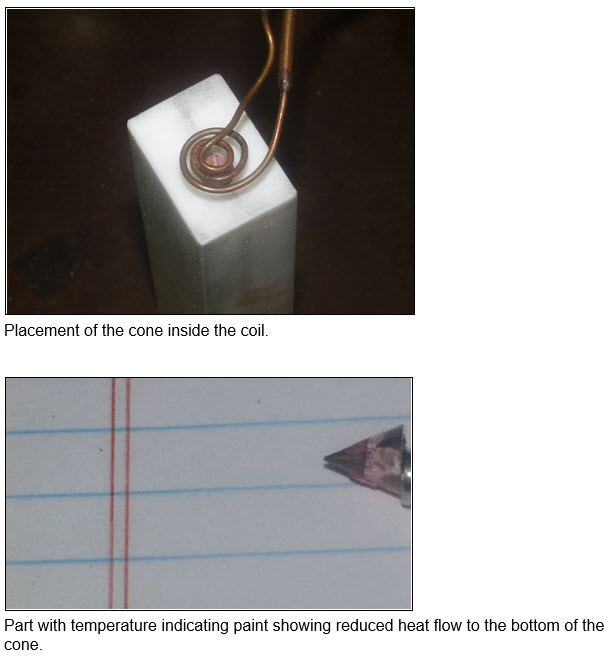

Ambrell EASYHEAT 1.2 kW, 150-400 kHz induction heating system equipped with a remote workhead A three-turn pancake coil designed specifically for this application

Materials:

Kovar cone, base 3/8 in (9.5mm) diameter, cone 3/8 in (9.5mm) high, solder

Temperature:

300 °F (149 °C)

Frequency:

242 kHz

Testing:

A three-turn pancake coil was used to heat the tip of the cone to 300 °F (149 °C) in 2-3 seconds. The coil design allows for easy placement of the fiber across the tip of the cone and reduces the heat flow to the bottom of the assembly for the manufacturing process

Benefits:

Speed: It took less than three seconds to complete this application, resulting in a boost in throughput for the client.

Precise, repeatable heating: Induction is a highly repeatable process that heats just the tip of the assembly, which is all that requires heating.

Safety: There is no open flame or hot iron with induction and it"s also hands free, which makes it safer than competitive heating methods

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000