Note: Soldering Co-axial Wire to a Metal Frame

Objective:

To heat a coaxial wire and a metal frame for a soldering application; the end product is a circuit board

End Product:

circuit board

Equipment:

Ambrell EASYHEATTM 2 kW, 150-400 kHz induction heating system equipped with a remote workhead A single position multiple-turn helical coil designed specifically for this application

Materials:

coaxial wire, metal frame, graphite cylinder

Temperature:

400 °F (204 °C)

Frequency:

250 kHz

Testing:

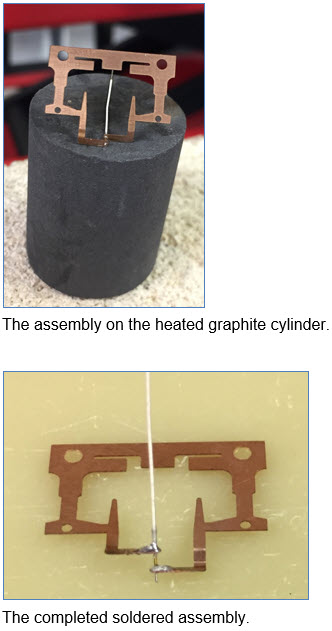

Initial tests were conducted to optimize the power delivered to the part. Given the small size of the part and the assembly's geometry, a graphite cylinder was required as a susceptor. When the graphite cylinder was heated to 400 °F (204 °C), the power was turned off and the wire assembly was placed on the cylinder. The solder liquefied at both joints in just five seconds. After the assembly cooled and the joints were solid, the assembly was removed from the surface of the susceptor and the process had concluded

Benefits:

-

Speed: It took just five seconds to heat the susceptor to temperature

-

Innovation from THE LAB: Ambrell"s Applications Engineers were able to devise an optimal solution despite small/challenging part geometry

-

Footprint: The EASYHEAT takes up a modest footprint, making it an easy addition into this client"s process

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000