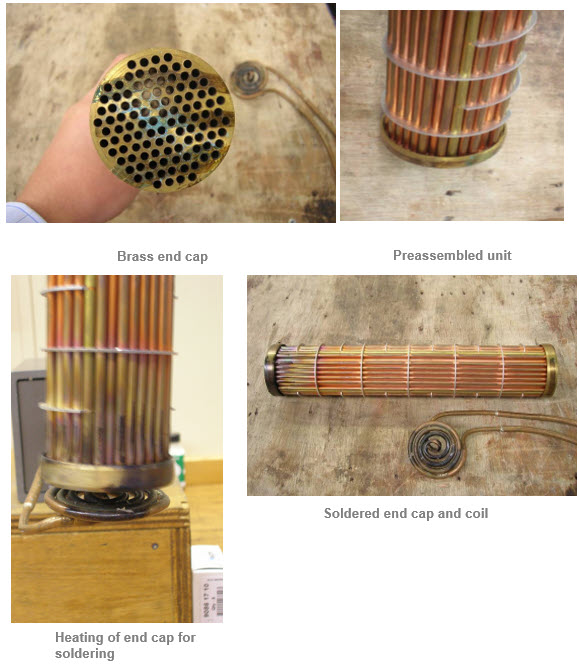

Note: Soldering Brass end cap on heat exchanger

Objective:

To solder a brass endcap onto a heat exchanger

End Product:

heat exchanger

Equipment:

Ambrell EASYHEAT 10 kW, 150-400 kHz induction heating system equipped with a remote workhead A dual four-turn pancake coil designed specifically for this application

Materials:

Preassembled heat exchanger with copper tubes and two brass endcaps 2.36 in (60 mm) OD, 0.08 into 0.12 in (2 to 3 mm) thick at both ends, liquid solder

Temperature:

302 °F (150 °C), 482 °F (250 °C)

Frequency:

237 kHz

Testing:

The dual four-turn pancake coil was used to solder two brass caps per cycle. Liquid solder was squirted onto the end cap and was heated for 18 seconds at 302 °F (150 °C) to burn off the flux. Then the heat was increased to 482 °F (250 °C) for 15 seconds to solder the parts.

Benefits:

Speed: Compared to a hot plate, induction heating was able to heat two parts in 30 seconds versus one part in 60 seconds with the hot plate.

Precise, repeatable, even heating: Induction is a highly repeatable process that also offers even heating, which this process required.

Production: The rapid speed of induction enabled them to increase their production levels.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000