Note: Soldering a Radio Antenna

Objective:

To heat a coaxial antenna assembly to 600 °F within 2 seconds for a soldering application. The goal to improve on an existing procedure with a soldering iron which required 10 to 15 seconds.

End Product:

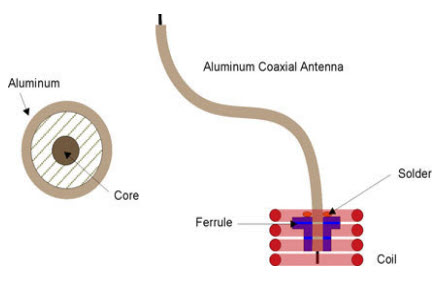

antenna

Equipment:

Ambrell 1 kW power supply, remote heat station with one 1.2μF capacitor and a specially designed induction coil.

Materials:

.250 in diameter aluminum antenna assembly, aluminum ferrule, solder paste, temperature indicating paint

Temperature:

600 °F

Frequency:

333 kHz

Testing:

Initial tests were conducted with temperature indicating paint to establish a heating profile and determine time-to-temperature. The solder paste was then applied to the antenna assembly and aluminum ferrule. RF power was applied for two seconds to heat and flow the solder joint.

Benefits:

Consistent and repeatable results were achieved within the required two-second time frame. A close examination of the solder joint indicated that the solder flowed well and formed a good, solid joint.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000