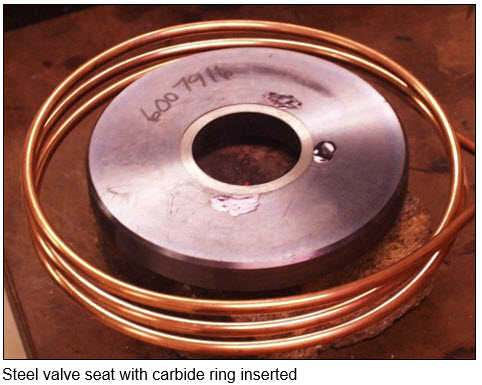

Note: shrink-fitting a carbide ring into a valve seat

Objective:

To shrink fit a carbide ring into a valve seat

End Product:

valve seat

Equipment:

Ambrell EASYHEATTM 10 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials:

Steel valve seat 6” (152.4mm) OD with 3” (76.2mm) ID hole & .75” (19mm) thick, carbide ring

Temperature:

500 ºF ( 260 ºC)

Frequency:

185 kHz

Testing:

A three-turn helical coil is used to heat the steel valve seat. The steel valve seat is placed in the coil and heated for 50 seconds to enlarge the center hole and drop the carbide ring in for the shrink fitting process.

Benefits:

• Accurate and repeatable results

• Ease of integration into existing production lines

• Energy efficient, only heats the part, not the atmosphere around it

• Hands-free heating that involves no operator skill for manufacturing

• Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000