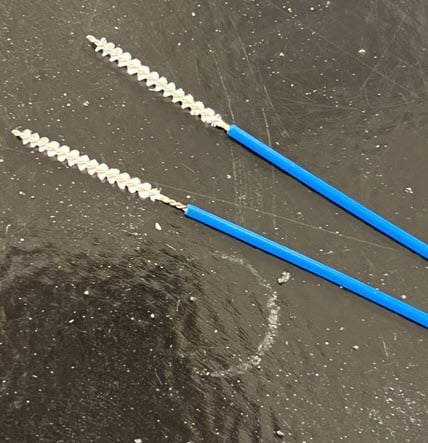

Note: Staking a Stainless Steel Brush

Objective:

Heat customer supplied stainless steel brush to 400 °F for insertion to plastic part

End Product:

Stainless steel brush

Equipment:

Ambrell EASYHEAT 5.0 kW, 150-400 kHz solid state induction power supply, equipped with a remote work head containing two 1.5 μF capacitors.

Materials:

Customer supplied stainless steel brush & plastic part

Temperature:

400 °F(200 °C)

Frequency:

350 kHz

Testing:

A custom-designed multi turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. Once a satisfactory heat pattern was achieved in the time frame allowed, samples were run at multiple different settings.

Heating time with the EASYHEAT power supply shows that a temperature can be achieved within 5 seconds. The wire can then be moved to perform the customer application.

Wire painted with temperature indicating paint to check if a static test with 5 seconds would heat and melt the temperature paint.

Paint has melted and turned clear showing that the temperature has been reached.

Tests were conducted using the EASYHEAT 5.0 kW power supply.

Benefits:

-

Speed: The client was able to braze the assembly within their targeted time frame.

-

Safety & Efficiency: There is no open flame with induction heating, and it also introduces less heat into the work environment. It is also more efficient than most alternative heating methods such as torch heating.

-

Repeatability: The client can expect the same result in the same amount of time every single time with induction heating.

-

Lab Expertise: THE LAB at Ambrell designed a solution that met the client’s goals.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000