Note: Pre-heating a steel transaxle tube (welding)

Objective:

To pre-heat a steel tube for a welding application

End Product:

Automotive transaxle.

Equipment:

Ambrell EKOHEAT 45 kW, 50-150 kHz induction heating power supply with a remote workhead containing four 2.0 μF capacitors

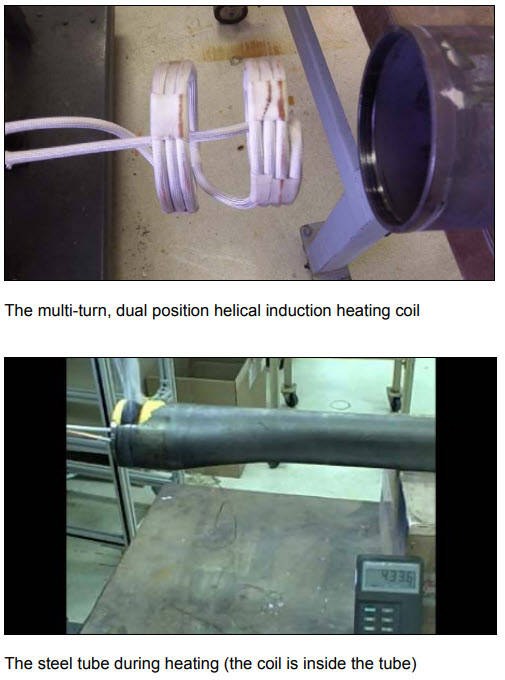

A multi-turn, dual position helical induction heating coil designed and developed for this application

Materials:

Steel tube 3.6 in (91 mm) OD

Temperature:

752 °F (400 °C)

Frequency:

90 kHz

Testing:

Two heat zones, about 0.5â (13 mm) wide, will be heated. The dual position helical coil is designed for this application. The 90 kHz operating frequency reduces energy loss in the internal induction coil and ensures optimum coupling efficiency to the steel transaxle. Temperature indicating paint was applied to the tube. The coil was then inserted inside the part. Power was turned on until the paint melted and turned clear, which took just five seconds. That indicated that the part had achieved temperature.

Benefits:

-

Speed: Induction was able to achieve the clientâÂÂs targeted speed

-

Repeatability: Induction is able to achieve an identical result consistently, which is an advantage over torch heating

-

Energy savings: Induction is a more efficient heating method than other heating options such as torch heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000