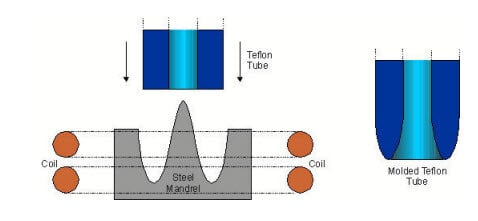

Note: Molding a teflon catheter tip

Objective:

Heat a water-cooled steel mandrel to 700 °F (371 °C) to form a high quality Teflon catheter tip.

End Product:

Catheter

Equipment:

Ambrell 3 kW induction heating system, equipped with a remote workhead containing one 0.66 μF capacitor.

An induction heating coil designed and developed specifically for this application.

Materials:

Teflon catheter tubing

mandrel assembly

Temperature:

600-700 °F (315-371 °C)

Frequency:

376 kHz

Testing:

A two-turn coil is used to heat the steel mandrel to 660 °F (371 °C) in 2.7 seconds. To form the catheter tip, RF power is applied while the catheter is held over the mandrel. The tubing is then pushed on to the mandrel to form a consistent, even tip.

Benefits:

-

Precise, repeatable application of heat

-

Non-contact heating

-

Faster cycle times

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000