Note: Metal-to-Plastic Insertion with a Steel Insert

Objective:

To heat a magnetic steel insert for a metal-to-plastic insertion application for a supplier to an engine manufacturer

End Product:

Generic

Equipment:

Ambrell EKOHEAT 15 kW, 50-150 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

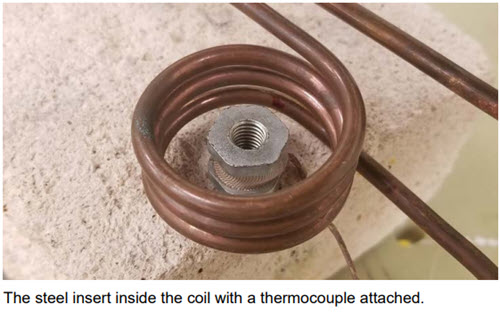

Magnetic steel insert 0.63 in (16 mm) diameter

Temperature:

500 °F (260 °C)

Frequency:

N/A

Testing:

During testing a thermocouple was used to measure the temperature of the part during and after heating. It was placed onto the outer diameter in the middle of the insert. The power was turned on for five seconds and the part was monitored during heating and for 15 seconds after. After being heated to temperature the insert did not cool down below 300 °F (149 °C) in that time period. The temperature actually increased due to the upper and lower sides of the insert getting hotter during heating and conducting the heat towards the center after the induction was turned off. This was beneficial as the client needed a few seconds after heating for the robot to place the insert.

Benefits:

-

Speed: The client requested a system that would meet their time objectives, which the EKOHEAT did

-

Footprint: An EKOHEAT and its workhead require a minimal footprint, saving the client valuable floor space compared to heating alternatives

-

Safety: The client wanted a precise, flameless heating method for their new application, which induction is

-

Expertise: The client took advantage of THE LABâÂÂs expertise to prove out their process

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000