Note: Metal-to-Plastic Insertion with a Brass Shaft

Objective:

To heat a brass shaft for a metal-to-plastic insertion application; the client used a torch previously

End Product:

Grinder gear assembly

Equipment:

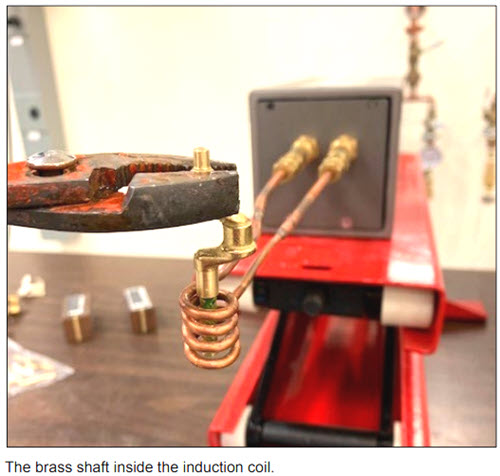

Ambrell EASYHEAT 2.4 kW, 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Brass shaft 0.187 in OD x 1 in / 4.75 mm OD x 25.4 mm)

Temperature:

400 °F (204 °C)

Frequency:

325 kHz.

Testing:

A custom-designed single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. Temperature indicating paint was then applied to the part, which dissolves when the part reaches the target temperature. It was observed that it took 2.5 seconds to heat the sample to temperature, which met the client's objectives.

Benefits:

-

Speed: The client requested a system that would meet their time objectives, which the EASYHEAT did.

-

Footprint: Multiple torches were required for this application previously, so the compact EASYHEAT minimized the required footprint for heating.

-

Safety: The client wanted a precise, flameless heating method as they previously used a torch.

-

Repeatability: With induction you can expect the same result every time, while variability is often observed with a torch.

-

Expertise: The client took advantage of THE LABâÂÂs expertise to prove out their process

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000