Note: Metal-to-plastic insertion of threaded magnetic steel inserts

Objective:

Heat magnetic steel inserts of two sizes to 500 °F (260 °C) in two seconds per part for a metal-to-plastic insertion application. The steel inserts are part of a car door handle.

End Product:

Automotive door handles

Equipment:

Ambrell EASYHEAT 0224, 2 kW induction heating system equipped with a remote heat station containing two 0.66 μF capacitors.

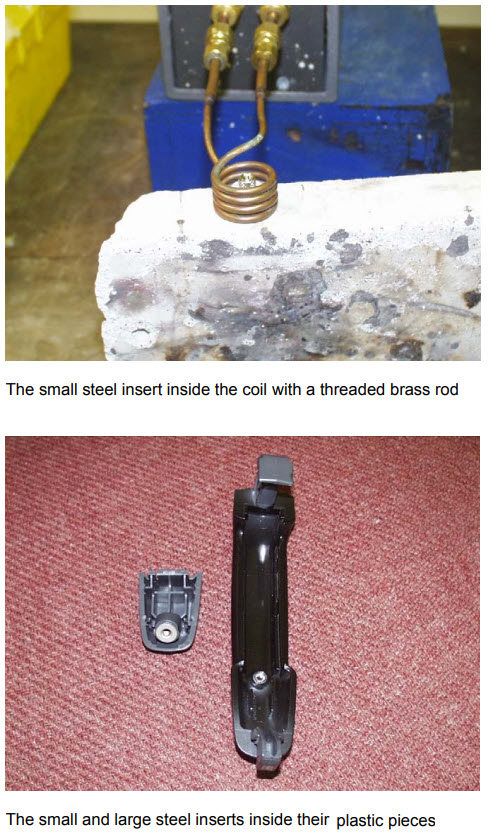

A single-position, four-turn helical coil designed and developed to generate the required heat for this application.

Materials:

Large steel insert 0.375 in (9.5mm) OD

Small steel insert 0.275 in (7.0 mm) OD

Threaded brass rod

Temperature:

500 °F ( 260 °C)

Frequency:

197 kHz

Testing:

Testing was conducted to optimize the power delivered to the parts. A threaded brass rod was inserted into the smaller part and the part was heated for two seconds to achieve the targeted temperature. The brass rod was used to handle the heated part so it could be immediately inserted into the mating plastic part, and it was then removed. The larger part also heated to temperature within two seconds and the same process was followed.

Benefits:

-

Heating speed: The client targeted a heating time of two seconds per part, which was achieved

-

Repeatability: This process is repeatable and can be integrated into a production process

-

Responsiveness: Outdated equipment and poor responsiveness drove this customer to a new vendor who could help them with new or improved processes for new or enhanced solutions

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000