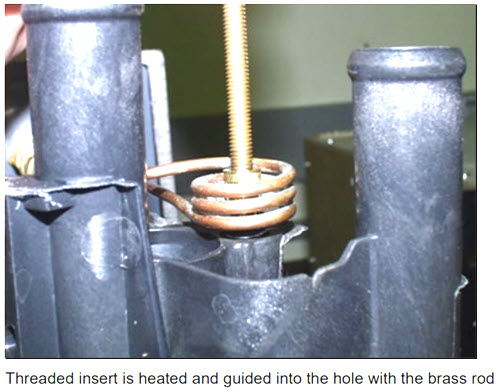

Note: Inserting threaded brass parts into plastic thermostat housing

Objective:

Inserting brass threaded inserts into 7 locations on a plastic thermostat housing.

End Product:

Thermostat housing

Equipment:

Ambrell EASYHEAT 3.5 kW, 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Brass inserts .25 in (6.3 mm) diameter, plastic thermostat housing

Temperature:

700 °F (371 °C)

Frequency:

N/A

Testing:

This application has three different coils for varying hole patterns. A three-turn oblong coil is used to heat 2 brass inserts in close proximity. The inserts are heated in the coil above the insertion hole for 10 seconds to reach 700 °F (371 °C). The inserts are then pushed into the holes for placement. The second hole pattern requires a two place, three turn coil and the third pattern requires a three place, three turn coil. All three applications reach 700 °F (371 °C) in 10 seconds and can be heated using three 3.5 kW units.

Benefits:

-

Hands-free heating that involves no operator skill for manufacturing

-

Simplified fixturing

-

Faster production time

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000