Note: Heating Steel Inserts for Metal-to-Plastic Insertion

Objective:

Heat magnetic steel inserts into molded plastic without cracking the molded plastic

End Product:

Magnetic steel inserts

Equipment:

Ambrell EASYHEAT 2 kW, 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Molded plastic and magnetic steel inserts

Temperature:

400 °F (204 °C)

Frequency:

267 kHz

Testing:

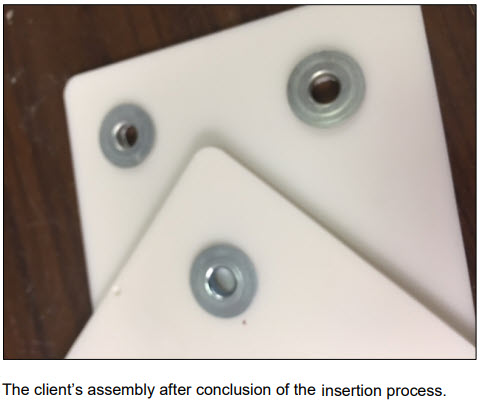

A specially designed multiple turn, two position helical coil was developed for this heating application. Initial tests were conducted to optimize power delivery. Temperature indicating paint was applied to the part and it dissolved when the part reached 400 °F (204 °C). A plastic sheet was placed over the coil and the steel insert was then pressed into the plastic part and the induction power was turned on. It took 5 seconds with a 2 kW EASYHEAT to reach temperature, which melted the plastic for a solid bond without cracking the molded plastic.

Benefits:

-

Speed: The client requested a system that would meet their time objectives which the 2 kW EASYHEAT easily did, boosting the clientâÂÂs throughput

-

Footprint: An EASYHEAT and a workhead requires a minimal footprint, saving the client floor space compared to heating alternatives

-

Integration: The compact EASYHEAT can be easily integrated into the clientâÂÂs manufacturing process

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000