Note: Heating steel for insertion into polypropylene

Objective:

Heating magnetic steel to 300 °F (149 °C) for insertion into a polypropylene board

End Product:

Pallets

Equipment:

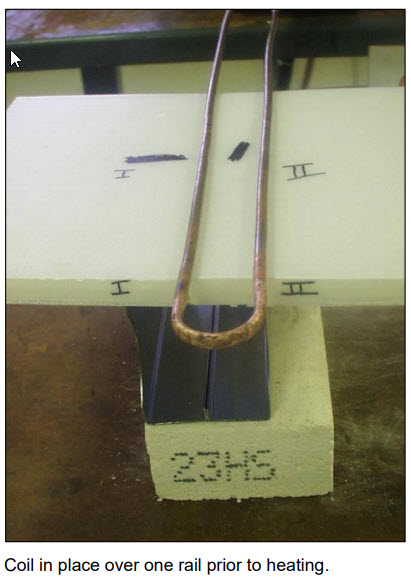

Ambrell EKOHEAT 40 kW, 50-150 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Hollow steel beam with two rails 3 in (76.2 mm) apart with steel barbs 0.25 in (6.35 mm) long and 0.04 in (1.02 mm) thick

polypropylene sandwich-ribbed reinforced board .50â (12.7 mm) thick

Temperature:

300 °F (149 °C)

Frequency:

108 kHz

Testing:

A single turn channel coil was used to heat the steel beam. The rail reached 300 °F (149 °C) in 20 seconds. The polypropylene board was pushed down on the steel beam to join the metal-to-plastic bond.

Benefits:

-

Hands-free heating that involves no operator skill for manufacturing

-

Faster production time

-

Even distribution of heating

-

âÂÂGreenerâ manufacturing of pallets using reusable, recyclable materials

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000