Note: Heating four brass inserts for a plastic motor housing

Objective:

To heat brass inserts to required temperature for a metal-to-plastic insertion application

End Product:

Motor housing

Equipment:

Ambrell EASYHEAT 2 kW, 150-400 kHz induction heating system equipped with a remote workhead containing two 0.33 μF capacitors

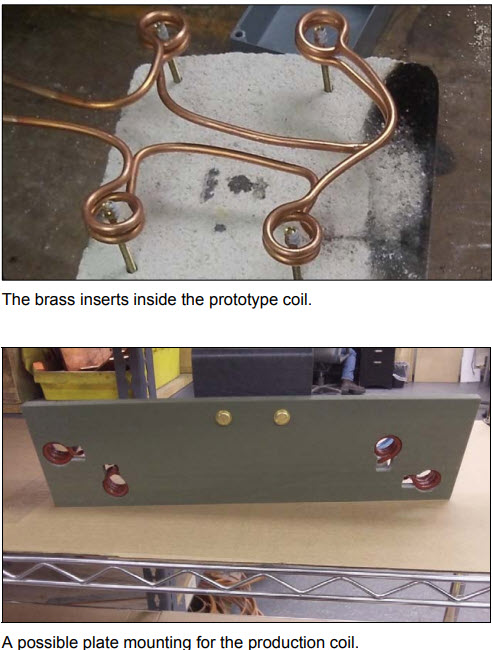

A four position, two turn helical induction heating coil designed and developed to generate the required heat for this heat staking application

Materials:

Customer-supplied 0.18 in (4.6 mm) O.D. brass insert

Plastic housing

Temperature:

1050 °F (566 °C)

Frequency:

257 kHz

Testing:

Four inserts were heated in a prototype coil. The inserts were threaded onto brass rods for testing purposes. The parts heated to temperature within 15 seconds. The production coil will be considerably more sophisticated with the possibility of polymer tubes to provide additional water flow for higher production rates and a plate mounted to the coil to facilitate repeatable, consistent heating.

Benefits:

-

Speed: The parts heated to required temperature in just 15 seconds

-

Repeatability: Induction is a highly repeatable heating method, and a coil plate could offer protection against operator movement/errors

-

Integration into Production: The EASYHEAT and its workhead are small, which makes it easy to implement within a production line given the minimal required footprint

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000