Note: Heating brass inserts

Objective:

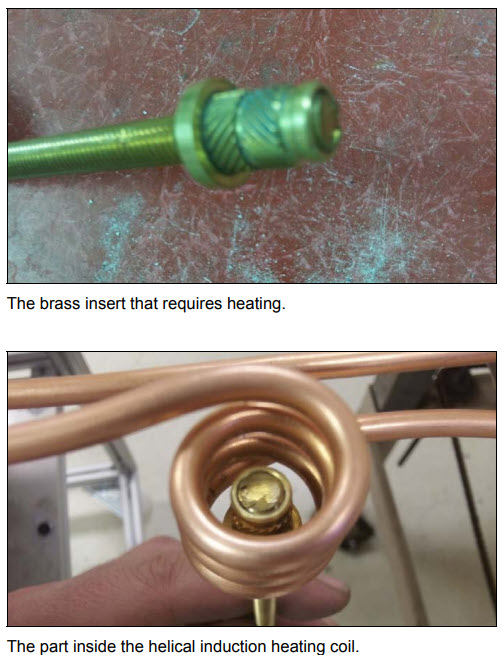

To heat brass inserts for a metal-to-plastic insertion application

End Product:

Automotive valve cover

Equipment:

Ambrell EASYHEAT 10 kW/150-400 kHz induction heating system equipped with a remote workhead containing two 1.0 μF capacitors

A three turn, helical induction heating coil designed and developed to generate the required heat for this application

Materials:

Customer supplied 0.33 in (8 mm) O.D. knurled brass insert

Temperature:

752 °F (400 °C)

Frequency:

184 kHz

Testing:

Inserts were placed into the coil and heated. Thermal indicating paint was used to specify when the targeted temperature was achieved. The inserts heated to temperature within the desired heating cycle time of four seconds. The coil that was designed for this application can be used for up to six brass inserts. Four coils can be used so that the client can heat 22 brass inserts on a single manifold as desired.

Benefits:

-

Speed: A competitor couldnâÂÂt come up with a solution to help the client heat all of the inserts concurrently, but Ambrell was able to do so

-

High production rate: The solution from Ambrell enables the customer to improve its production rate

-

Innovation: AmbrellâÂÂs Applications Lab was able to solve a problem that a competitor couldnâÂÂt solve, which is a key benefit when purchasing induction solutions from Ambrell

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000