Note: Heating a Steel Pin for Fan Insertion

Objective:

To heat a steel pin for a metal-to-plastic insertion application

End Product:

Cooling fan shaft

Equipment:

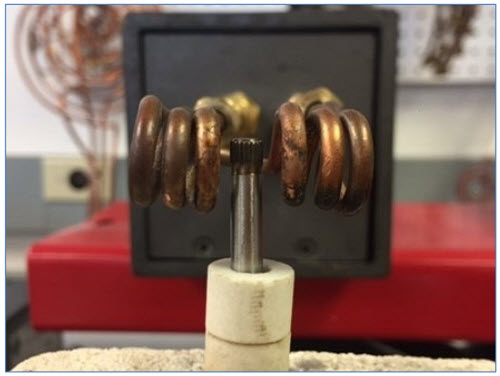

Ambrell EASYHEAT 2 kW, 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Ambrell EASYHEAT 2 kW, 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Temperature:

572 °F (300 °C)

Frequency:

340 kHz

Testing:

A custom-designed single-position multi-turn split helical coil was built to generate the required heating for this application. Temperature indicating paint was then applied to the tube, which dissolves when the part reaches the target temperature. It took just one second to heat the tube to the target temperature, which exceeded the client's requirement of 3 seconds.

Benefits:

-

Repeatability: The client can expect the same result every time with an Ambrell induction heating system, increasing quality

-

Speed: The client requested a system that would meet their time objectives, which the EASYHEAT not only met but exceeded

-

Footprint: An EASYHEAT and its workhead require a minimal footprint, saving the client valuable floor space compared to heating alternatives

-

Safety: The client wanted a precise, flameless heating method for their new application, which induction is

-

Expertise: The client took advantage of THE LABâÂÂs expertise to prove out their process.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000