Note: Heat Staking Steel Parts

Objective:

To heat steel inserts to be placed into a plastic frame

End Product:

Automotive part.

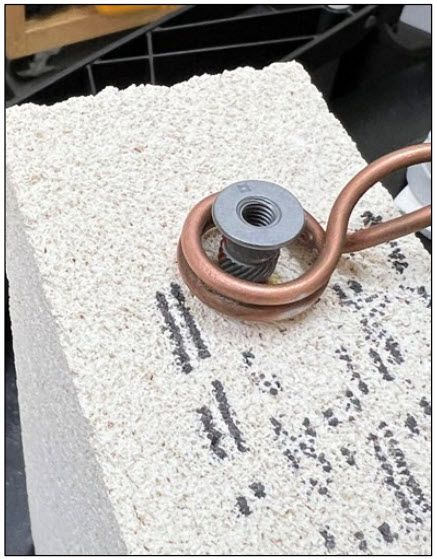

Equipment:

Ambrell EASYHEAT 6 kW, 150-400 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Steel inserts

plastic frames

Temperature:

N/A

Frequency:

360 kHz

Testing:

A custom-designed multiple-turn helical coil was built to generate the required heating for this heating staking application. Initial tests were conducted to optimize the power delivered to the inserts. Samples heated to temperature in just over one second.

Benefits:

-

Speed: Induction can rapidly heat their inserts, helping them to meet their production objectives.

-

Repeatability: With induction heating, you will get the same result time after time, making it ideal for a high-volume manufacturing process like this one.

-

Efficiency: Induction delivers most of the energy into the part, unlike competitive heating methods, leading to significant energy savings.

-

Footprint: Induction requires less floor space when compared to an oven.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000