Note: Curing a coating; both sides aluminum piston

Objective:

Curing a coating on both sides of an aluminum piston at a rate of 1 in (25.4 mm) per second

End Product:

Aluminum piston

Equipment:

Ambrell 50 kW induction heating system, equipped with a remote workhead containing three 26.8μF capacitors for a total of 80μF

An induction heating coil designed and developed specifically for this application.

Materials:

4 aluminum pistons weighing 1 lb (.45 kg) each, 3.75 in (95.25 mm) dia and 2.5 in (63.5 mm) high

Temperature:

225 °F (107.2 °C)

Frequency:

6 kHz

Testing:

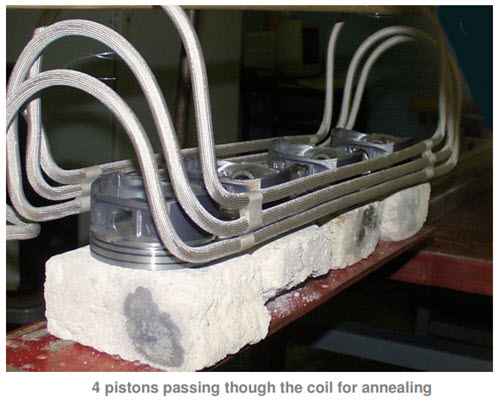

A three-turn channel coil 19 in (48.26cm) long is used to anneal 4 pistons running though the coil with a distance of 6 in (15.24cm) between centers. The parts run at a rate of 1 in (25.4mm) per second and the 4 parts reach 225 °F (107.2 °C) and are annealed in 40 seconds.

Benefits:

-

Hands-free heating that involves no operator skill for manufacturing

-

Ideal for in-line production processes because of its ability to produce repeatable, rapid and accurate heating cycles

-

Improved thoughput

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000