Note: Brassiere Underwire

Objective:

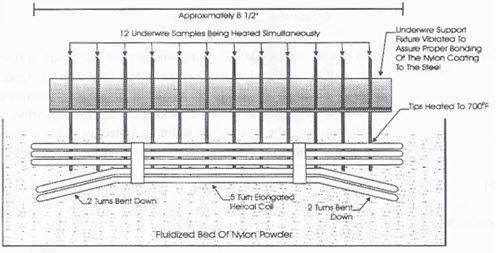

To heat the ends of 0.072 in spring wire, spaced 1/2 in apart, uniformly for the application of nylon powder on a 1 in length of the end. Once heated to 700 °F the nylon powder fuses to the wire creating a protective coating. Underwires have a past history of poking through the supportive garment and scratching the wearer. By adding a protective nylon coating at the ends of the wire form, this uncomfortable situation is avoided.

End Product:

Brassiere underwire

Equipment:

Ambrell 2.5 kW induction heating system including one remote heat station containing two capacitors with a total value of 0.66 μF

a unique five-turn elongated helical coil measuring 2.5 x 8.5 x 2 3/4 in with the lower two turns angled down at the ends.

Materials:

Spring wire

Nylon powder

Temperature:

700 °F

Frequency:

92 kHz

Testing:

The 2.5 kW system along with a unique five-turn elongated helical coil was used to achieve the following results:

700 °F was reached with a twelve-second machine cycle.

A uniform coating was produced as a result of even heating due to the unique five-turn elongated helical coil.

Twelve wire samples were heated simultaneously in the unique work coil.

Benefits:

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000