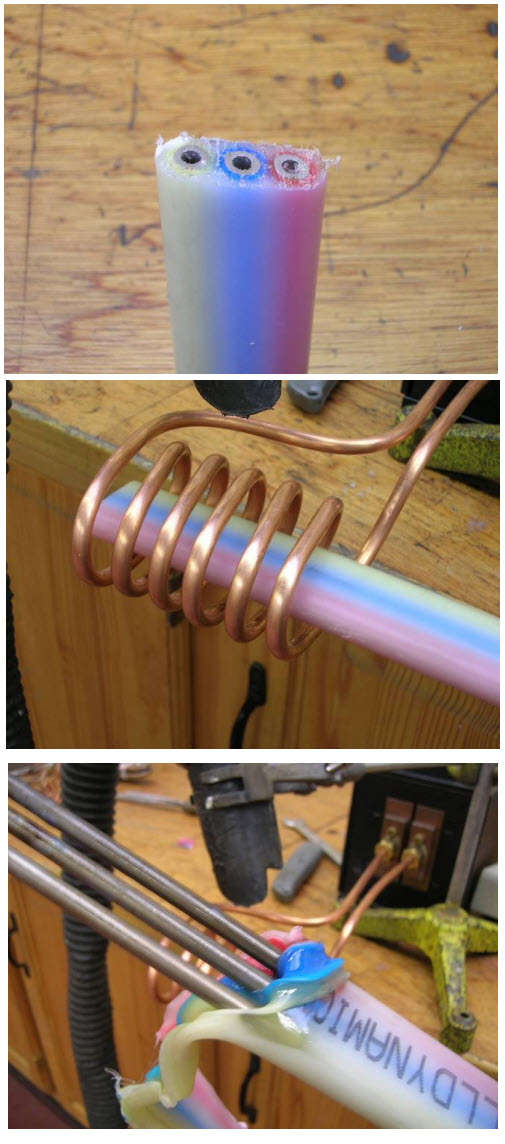

Note: Remove plastic coating from steel tubes

Objective:

Recover the polypropylene insulation from hollow steel tubes to allow recycling of both the tubes and the insulation.

End Product:

Hollow steel tubes

Equipment:

Ambrell 5 kW induction heating system, equipped with a remote workhead containing one 1.5μF capacitor

An induction heating coil designed and developed specifically for this application.

Materials:

Hollow steel tubes 1/8 in (0.318 cm) to 5/8 in (1.59 cm) ID

Protective polypropylene coating

Temperature:

150 °C (302 °F)

Frequency:

185 kHz

Testing:

A six-turn letterbox shaped coil is used to heat the inner steel pipes. The plastic coating is softened enough to be easily removed and recycled. The time required to melt the plastic from one meter of wire is approximately 45 seconds. This varies based on the diameter of the tube.

Benefits:

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000