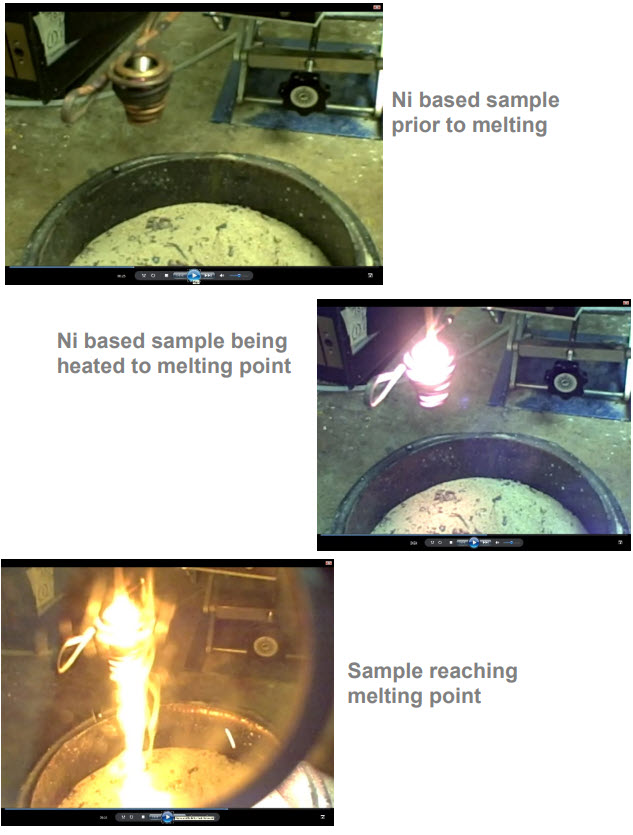

Note: Melting of Ni based alloy samples

Objective:

Superheating molten metal for a different sample mass.

End Product:

Ni mass

Equipment:

Ambrell EASYHEAT 10 kW, 150-400 kHz solid state induction power supply with a workhead and coil specifically designed for this application.

Materials:

Ni based alloy between 10 - 18g (0.35 - 0.63 ounce)

Temperature:

2642 - 2912 °F (1450 - 1600 °C)

Frequency:

268 kHz

Testing:

A single-position nine-turn helical coil was used to generate the required heating for the application. The 16-gram slug of steel was placed into the coil and supported with a ceramic rod. When the sample was melted the part changed shape to an inverted tear drop.

The customer was looking for repeatable superheating of the molten metal for a different sample mass. They were holding parts on a copper hearth with a central hole. The testing met the client's objectives.

Benefits:

-

Hands-free heating

-

Involves no operator skill required for manufacturing

-

Even distribution of heating Fast, controllable temperature ramp

-

Consistent results

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000