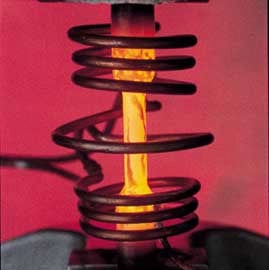

Materials Testing with Induction Heating

In materials testing, the relationship between the structure and the properties of materials are studied. This research often assesses important factors such as quality, safety and reliability and it is often used to produce new and better materials. Common applications and industries for materials testing includes microelectronics, mining, automotive, aerospace, nanotechnology, failure analysis, forensic engineering and more. Biomaterials, nanomaterials, polymers, thin films and ceramics are often areas of interest in this field.

Induction heating provides reliable, repeatable, precise, non-contact and energy-efficient heat in a minimal amount of time and is often the perfect fit for materials testing. Ambrell offers complimentary applications testing at its state-of-the-art applications laboratory. Contact us today to discuss your materials testing application!

Can we help?

- Home

- Applications

- Material Testing

Induction material testing Benefits

-

Meets tight production tolerances with precise localized heat to small areas creating pinpoint accuracy

-

Increases production rates with faster heating cycles

-

Reduces defect rates with repeatable, reliable heat

-

Eliminates variability from operator-to-operator, shift-to-shift

-

Maintains metallurgical characteristics of the individual metals

Our Induction material testing Systems and Equipment

AMBRELL CORPORATION

1655 Lyell Avenue

Rochester, NY 14606

United States

F: +1 585 889 4030

AMBRELL B.V.

Holtersweg 1

7556 BS Hengelo

The Netherlands

AMBRELL Ltd.

Unit 6, Space Business Centre

Tewkesbury Road

Cheltenham, GLOS, GL51 9FL

United Kingdom

F: +31 546 788 154