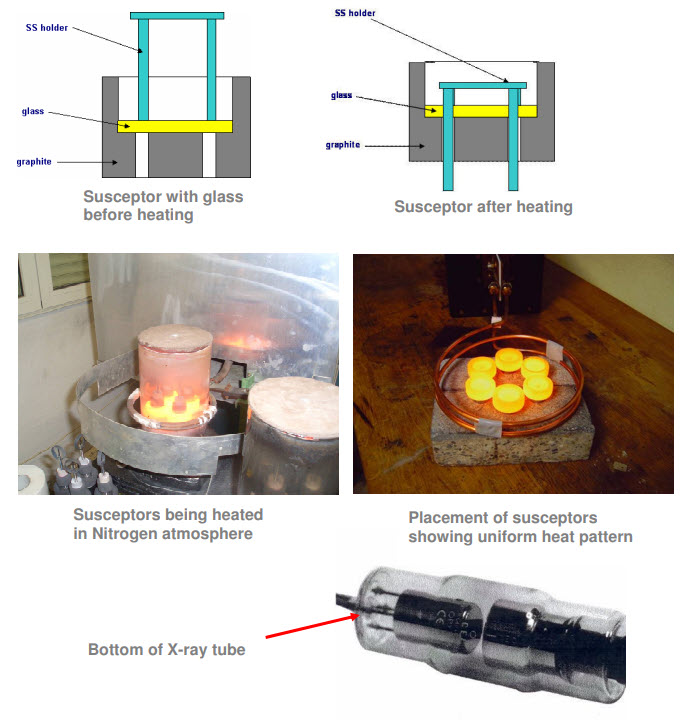

Note: Heating susceptor for glass reflow (X-ray tubes)

Objective:

Heat graphite susceptor for glass reflow in the manufacturing of x-ray tubes

End Product:

X-ray tubes

Equipment:

Ambrell 15 kW induction heating system, equipped with a remote workhead containing eight 0.3 μF capacitors for a total of 2.4 μF

An induction heating coil designed and developed specifically for this application

Materials:

Glass disc 0.98 x 0.12 in (25 x 3 mm), graphite susceptor

stainless steel holder

Glass bell jar 5.9 in (150 mm) IOD

Temperature:

1742 °F (950 °C)

Frequency:

84 kHz

Testing:

A two-turn helical coil is used for heating. Six graphite susceptors are placed in the nitrogen atmosphere with glass discs and a stainless steel holder. In 32 seconds the required temperature of 1742 °F (950ĂĹ C) is reached causing the glass to reflow & the stainless steel holder to melt through the glass.

Benefits:

-

Increased production, customer currently heating 4 susceptors

-

50% lower energy consummation

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000