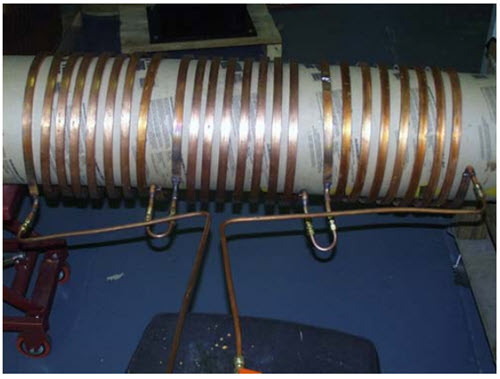

Note: Heating a 4-tube carbon susceptor

Objective:

A tubular carbon susceptor is held within an atmosphere controlled quartz chamber. Induction is used to heat the susceptor

End Product:

Susceptor

Equipment:

Ambrell EKOHEAT 50/10 induction heating system, equipped with a remote workhead containing three 26μF capacitors for a total of 78μF

A combination induction heating coil designed and developed specifically for this application.

Materials:

Customer-supplied carbon tube, 36â long, 4â âÂÂ

Temperature:

5400 °F (3000 °C)

Frequency:

8.5 kHz

Testing:

A 24-turn helical coil has been wound in three 1-foot sections with 14â â . The large ID of the coil is required to overcome the radiant losses at these high temperatures. Graphite felt insulation is used to fill the gap between the OD of the graphite and the ID of the coil/chamber. Testing supports feasibility of this application.

Benefits:

-

Flameless, precision heating of the susceptor

-

Uniform distribution and control of susceptor heating

-

Reduced conductive thermal losses

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000