Note: Heating a Steel Susceptor for Glass Cutting

Objective:

To heat a steel susceptor to heat glass rods for a glass cutting application.

End Product:

Glass rods

Equipment:

Ambrell EASYHEAT 1.2 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Materials:

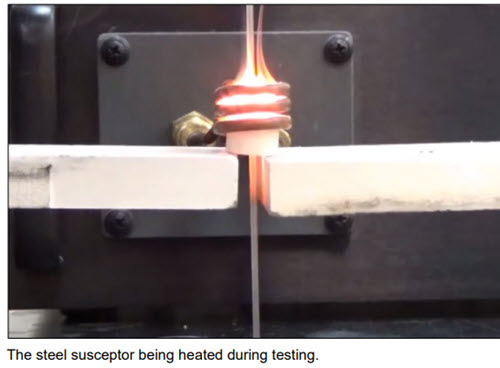

Steel susceptor

Temperature:

2000 °F (1093 °C)

Frequency:

309 kHz

Testing:

A custom-designed single-position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. A pyrometer was used to measure the temperature of the part until it reached the target. It was observed that it took 8 seconds to heat the sample to temperature and melt the glass.

Benefits:

-

Speed: Induction met the clientâÂÂs time objective for this susceptor heating application.

-

Repeatability: The client can expect the same result in the same amount of time every single time, which is ideal for their manufacturing process.

-

Safety: Induction has no open flame and is conducive to an automated manufacturing process

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000