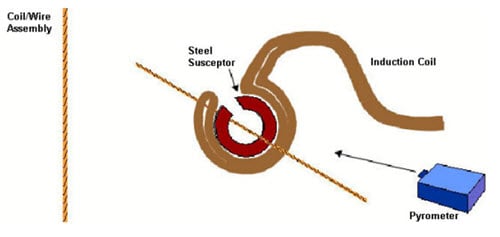

Note: Brazing a heat-sensing probe

Objective:

To heat a coil and a wire assembly to 1300 °F (704 °C) within 60 seconds for brazing.

End Product:

heat-sensing probe

Equipment:

Ambrell 1kW output, remote heat station containing one 1.2μF capacitor, a specially-designed induction coil

an optical pyrometer

stainless steel susceptor

zirconia felt to house the susceptor.

Materials:

Platinum coil

steel wire

braze paste

Temperature:

1300 °F (704 °C)

Frequency:

307kHz

Testing:

A C-shaped steel susceptor is used to ensure even heating and for ease of loading and unloading the samples. RF power from the power supply heats the susceptor to the required temperature of 1700 °F (926 °C) in 45 seconds. After braze paste is applied to the wire assembly, the assembly is placed inside the susceptor. It takes 3.5 seconds to heat the wire to the optimum brazing temperature of 1300 °F (704 °C) and the braze paste flows evenly and consistently.

Benefits:

-

Fast, accurate, repeatable heat

-

Ability to heat very small areas within precise production tolerances

-

Better joint quality, reduced oxidation

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000