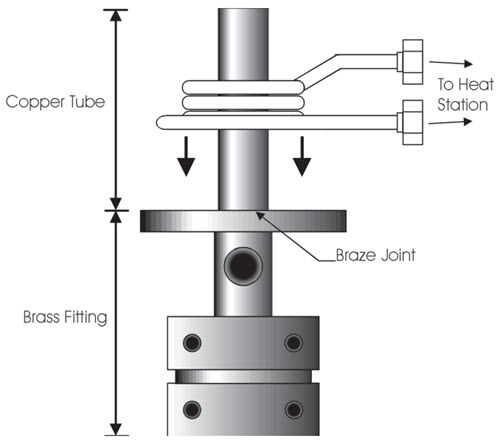

Note: Braze Copper Tube to Brass Fitting

Objective:

To use induction heating to braze a copper tube to a brass fitting using a preform braze wire. Processing is to occur under an atmosphere of Nitrogen and 4% hydrogen gas. The braze preforms melt at 1190 °F, but the parts need to be kept below 1300 °F. The parts need to be processed at a rate of 175 to 200 per hour which translates into 18 seconds of heating time per part.

End Product:

Copper/Brass tube

Equipment:

Ambrell 7.5kW output solid state induction heating power supply with three (3) busses, eight (8) capacitors totaling 0.66 μF, and a unique four turn helical coil.

Materials:

Copper Tubing Measuring 0.5" OD and 2" Long Brass fitting Braze Preform

Temperature:

Above 1190 °F but not to exceed 1300 °F

Frequency:

133 kHz

Testing:

The Ambrell 7.5kW output solid state power supply along with a unique four turn helical coil were used to achieve the following results.

Benefits:

-

The requested atmosphere was provided under a bell jar by supplying 95% Nitrogen/5%Hydrogen at a rate of 25-30 cfh.

-

A heating cycle of only 10 seconds was necessary to attain sufficient braze flow which surpasses the required limit of 18 seconds.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000