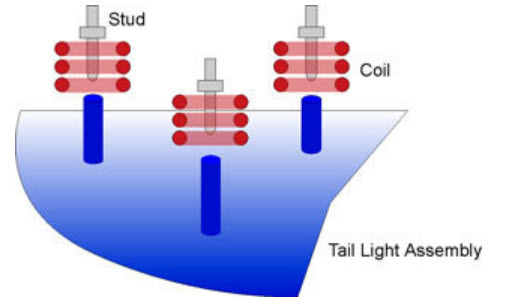

Note: Inserting Steel Studs into a Plastic Tail Light

Objective:

To heat threaded steel studs for insertion into a plastic tail-light assembly at 450°F. The total elapsed time for heating, inserting and re-solidifying the plastic must be within 15 seconds.

End Product:

Tail Light

Equipment:

Ambrell 1kW power supply, remote heat station with one 1.2 µF capacitor and a specially designed induction coil

Materials:

Threaded steel studs, molded polypropylene tail light

450°F temperature indicating paint

Temperature:

450 °F

Frequency:

160 kHz

Testing:

A special three position coil was designed to align with each of three stud locations on the molded part. Initial testing with temperature indicating paint confirmed that the studs could be heated within 5 seconds to 450°F. The molded part was clamped onto a table and the coil was positioned 1/2” above the stud locations. After RF power was applied for 5 seconds, the studs were pressed into the plastic and allowed to cool for 10 seconds.

The heated studs were easily pressed into the molded part. The total cycle time of 15 seconds for heating, inserting and resolidifying matched the application requirement.

Benefits:

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000