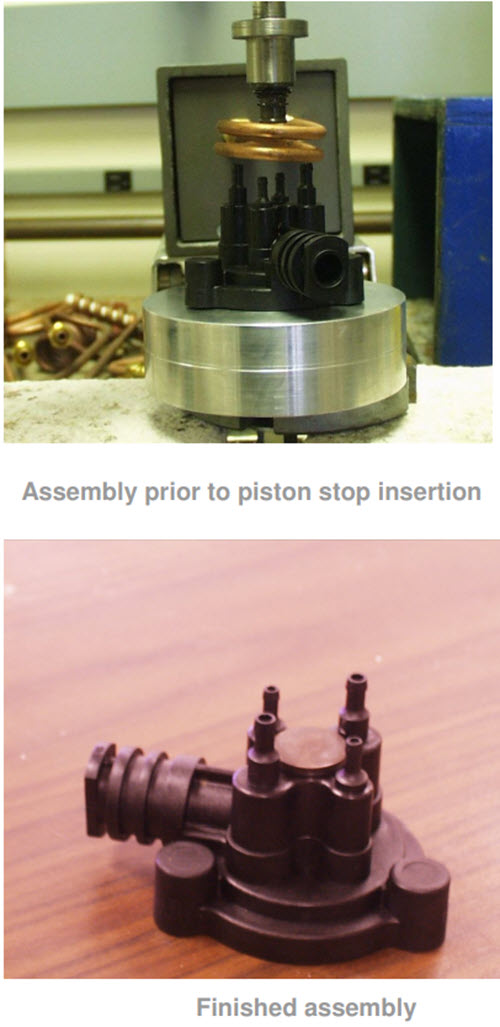

Note: Inserting a piston stop with o-ring into an oil pump

Objective:

To insert a piston stop with O-ring into an oil pump assembly

End Product:

Oil pump assembly

Equipment:

Ambrell 1 kW induction heating system, equipped with a remote workhead containing one 0.66µF capacitor.

An induction heating coil designed and developed specifically for this application.

Materials:

Rubber O-ring, steel piston stop and plastic pump body

Temperature:

650 ºF (343 ºC)

Frequency:

323 kHz

Testing:

A two-turn helical coil is used to heat the piston stop to 650ºF (343ºC) for 8-10 seconds prior to insertion into the black plastic pump body. The piston stop with the O-ring is then inserted into the pump body. Air is supplied to cool the steel insert quickly so that the O-ring does not melt. The piston stop is inserted into the pump body and is held in place during cooling and creates the bond.

Benefits:

-

Increased production speed

-

Simpler tooling for customer

-

Hands-free heating that involves no operator skill for manufacturing

-

Even distribution of heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000