Note: Heating magnetic steel for insertion into polypropylene for pallet manufacturing

Objective:

Heating magnetic steel to 300 ºF (149 ºC) for insertion into a polypropylene board.

End Product:

Pallet

Equipment:

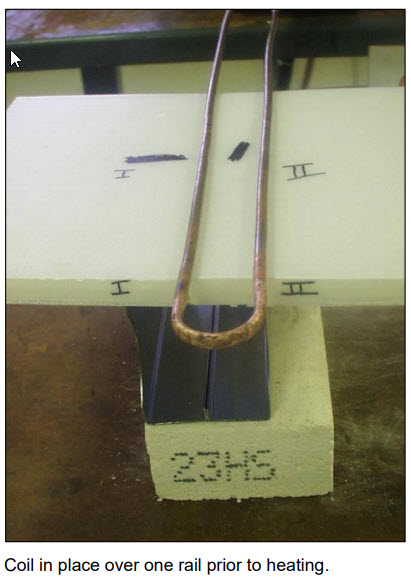

Ambrell EKOHEAT® 40 kW, 50-150 kHz induction heating system with a workhead and coil specifically designed for this application

Materials:

Hollow steel beam with two rails 3” (76.2 mm) apart with steel barbs 0.25” (6.35 mm) long and 0.04” (1.02 mm) thick on each rail

polypropylene sandwich-ribbed reinforced board .50” (12.7 mm) thick

Temperature:

300 ºF (149 ºC)

Frequency:

108 kHz

Testing:

A single-turn channel coil was used to heat the steel beam. The rail reached 300 ºF (149 ºC) in 20 seconds. The polypropylene board was pushed down on the steel beam to join the metal-to-plastic bond.

Benefits:

-

Hands-free heating that involves no operator skill for manufacturing

-

Faster production time

-

Even distribution of heating

-

Greener manufacturing of pallets using reusable, recyclable materials

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000