Note: Brass Inserts

Objective:

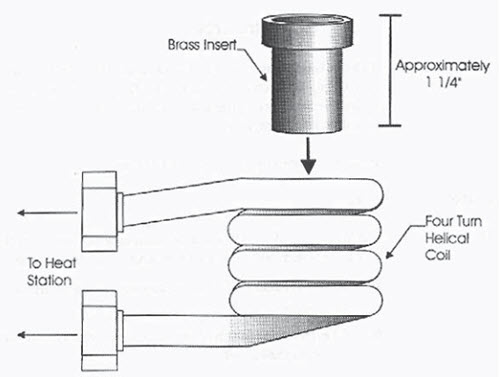

To heat a brass insert, measuring 1/2" OD and 1 1/4" long, to a temperature of 550 °F for insertion into a plastic part. Heating is to be accomplished within 5 seconds, and can be done in a helical coil since pick-and-place manufacturing is employed.

End Product:

Brass insert

Equipment:

Ambrell 3 kW system including one (1) remote heat station containing one 1.0 µF capacitor, and a four-turn helical coil made from 3/16" copper tubing and measuring 7/8" long with a 5/8" ID.

Materials:

Brass insert measuring 1/2" OD and 1 1/4" long.

Temperature:

550 °F

Frequency:

422 kHz

Testing:

550 °F was reached in 2.5 seconds, surpassing the customers requirement of 5 seconds. An even heating pattern on the insert was observed as a result of the four-turn helical coil.

Benefits:

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000