Induction hardening Videos

See the ways that induction heating is being used for hardening a wide range of parts. We may have already solved your process heating challenge!

Can we help?- Home

- Learn

- Application Videos

- Hardening Videos

Hardening with Induction

An Ambrell EASYHEAT system is used to harden a metal cross member. It is heated to 1600 deg. F in only 5 seconds!

A Steel Fitting

In this video, a steel fitting is heated with an Ambrell EASYHEAT induction heating system in 12.5 seconds then quenched.

Fastener Tips

In this application video, the tip of a steel fastener is heated with an Ambrell EASYHEAT Induction heating system, then quenched.

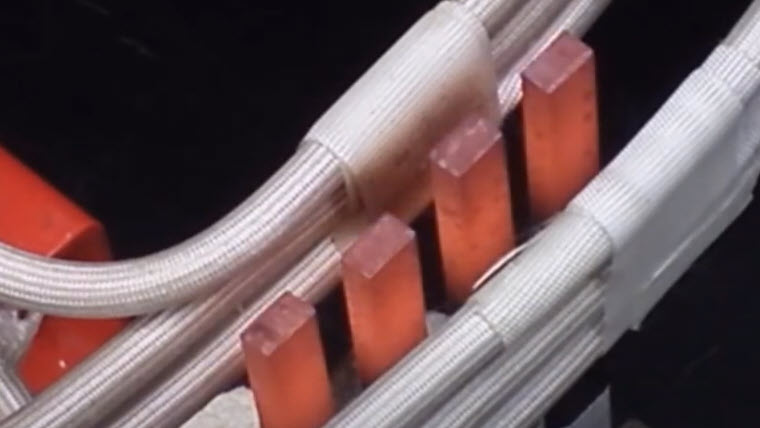

A Fastener Tip

In this application video a fastener tip is hardened using an Ambrell EKOHEAT induction system with a channel coil.

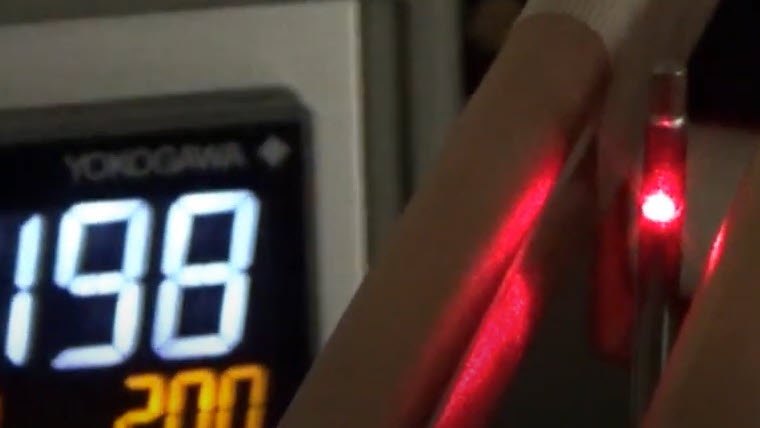

A Cutting Tool

In this video a part for a cutting tool is hardened using a pyrometer and an Ambrell EASYHEAT induction heating system.

A Steel Bar

In this application video, a steel bar is hardened with an Ambrell EASYHEAT induction heating system.

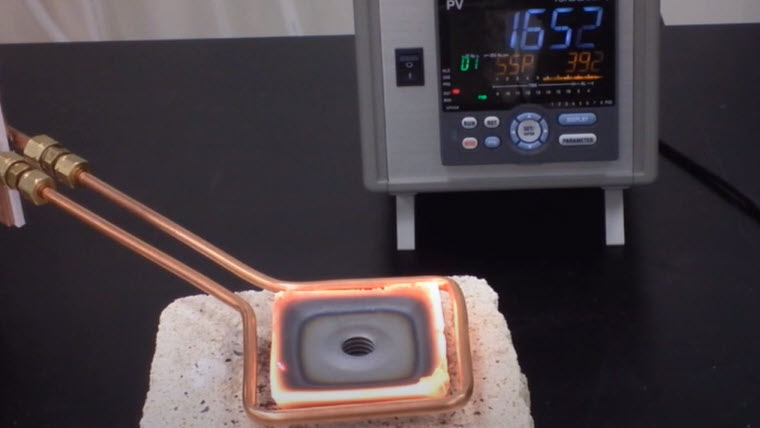

A Hole Saw

Heated to 1200C within 5 seconds with an Ambrell EKOHEAT 45kW induction heating system for a hardening application.

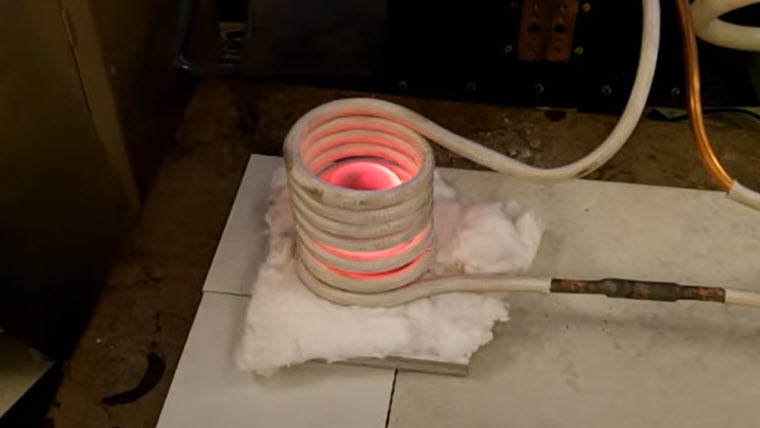

Saw Bit Teeth

In this video, an Ambrell EKOHEAT 45kW/100 kHz induction heating system is used to harden the teeth of a saw bit.

Case Hardening

In this video, a steel part is heated to 1600 F in just one second with an Ambrell EASYHEAT 10kW induction heating system

A Socket

Using an Ambrell EKOHEAT induction heating system, a socket is heated and quenched in order to harden it.

AMBRELL CORPORATION

1655 Lyell Avenue

Rochester, NY 14606

United States

F: +1 585 889 4030

AMBRELL B.V.

Holtersweg 1

7556 BS Hengelo

The Netherlands

AMBRELL Ltd.

Unit 6, Space Business Centre

Tewkesbury Road

Cheltenham, GLOS, GL51 9FL

United Kingdom

F: +31 546 788 154