Note: Hardening of Steel Cam Assembly

Objective:

To harden the perimeter of ¼” thick steel cam assemblies

End Product:

Steel cam assemblies

Equipment:

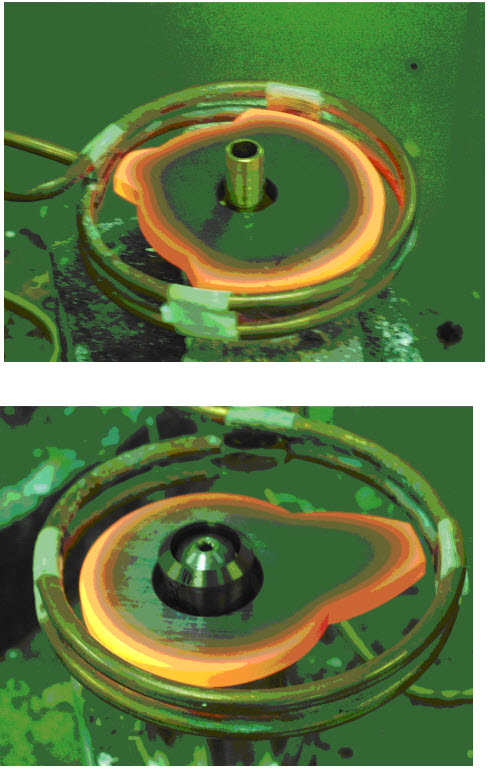

Ambrell 5 kW, induction heating system, equipped with a remote heat station containing one 1.0µF capacitor and an induction heating coil designed and developed specifically for this application

Materials:

¼” thick steel cam assemblies of varying geometries

Temperature:

1650 ºF (900 °C)

Frequency:

177 kHz

Testing:

A two-turn helical coil is used to heat the cams. The heat time varies from 120-150 seconds. After heating, the parts are quenched in water.

Benefits:

-

Uniform heating for uniform results

-

One coil can be used for many geometries

-

Consistent results from piece to piece

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000