Note: Preheating for forging of steel pins

Objective:

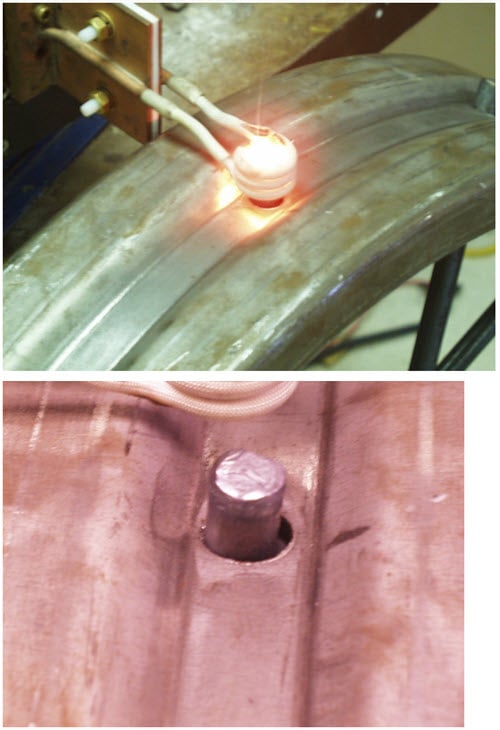

To heat magnetic steel pins (spokes) for forging on a rim without heat treating and weakening the rim. Previously, a torch was utilized and the heating time was 20 seconds.

End Product:

Wheel rim spokes

Equipment:

To heat magnetic steel pins (spokes) for forging on a rim without heat treating and weakening the rim. Previously, a torch was utilized and the heating time was 20 seconds.

Materials:

9/16” (14 mm) steel pins

Temperature:

2,000 ºF (1,093 ºC)

Frequency:

294 kHz

Testing:

A single=position three-turn helical coil was used, and the part was placed under the coil. The part was heated to the desired temperature within just seven seconds.

Benefits:

-

Fast, precise heating of the pin – 2 minutes and 36 seconds were saved on heating all of the rim’s pins when compared to using a torch.

-

The rim was not heated, which maintained its strength and durability.

-

Energy was saved due to the reduction in heating time.

-

There is more repeatability with induction when compared to using a torch.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000