Note: Preheating a brass assembly for forging blanks

Objective:

Preheat two brass parts to 1652 ºF (900 ºC) for a forging application in the wrist watch industry -- a key objective was to heat at a faster rate than their current induction heating system

End Product:

Brass assembly

Equipment:

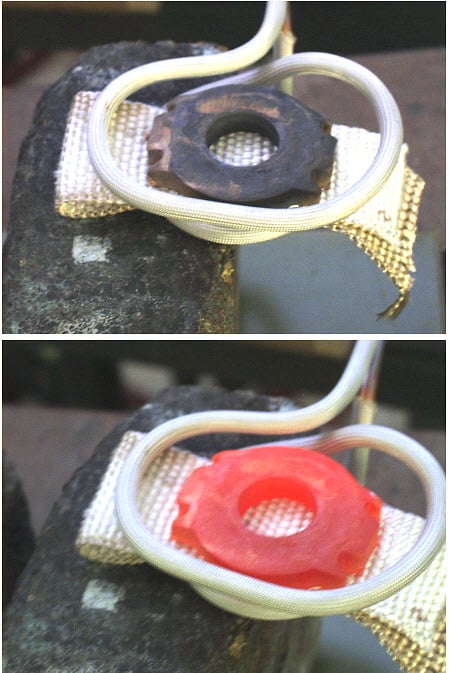

Ambrell EKOHEAT 30 kW, 50-150 kHz induction heating system, equipped with a remote workhead containing four 1.5 μF capacitors A double position three-turn pancake style coil with one helical turn

Materials:

A brass assembly consisting of two components with an outside diameter of 2” (51 mm)

Temperature:

1652 ºF (900 ºC)

Frequency:

120 kHz

Testing:

Initial tests were conducted to optimize the power delivered to the assembly. The assembly was placed 1 mm above the coil. The entire assembly was heated to 1652 ºF (900 ºC) in 16 seconds. Heat was generated in the bottom of the part, and heat was conducted to the entire assembly within 16 seconds.

Benefits:

-

Speed: The client was using a competitor’s system, and it as heating the assembly at a slower rate. They needed to increase their production rate, which this solution was able to achieve.

-

Service: The client was not receiving satisfactory support for their induction heating system, so they were looking to switch to a superior system that was built to their specifications and included the support they needed.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000