Note: Pre Heating Steel For Forging Horse Shoes

Objective:

To heat a strip of 1025 steel to 1800 ºF prior to a forging process for the production of horse shoes.

End Product:

1025 steel

Equipment:

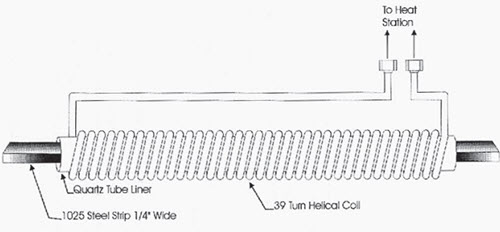

Ambrell 40 kW output solid state induction power supply including a heat station with a total capacitance of 0.5 µF.

Materials:

1025 Steel strip approximately 3/4" wide and 1/4" thick.

Temperature:

1800 ºF

Frequency:

75 kHz

Testing:

Presently, blanks are cut and heated in a gas fired oven and then forged in the press. With an induction coil in place, the steel would be fed continuously from a roll through the induction coil and into the forging press. In order to meet the increased production rate, heating of the 13" steel section must occur within 10 seconds.

Benefits:

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000