Note: Forming a Magnetic Steel Part

Objective:

To heat a magnetic steel part for a forming application; the client had been using a torch for the application

End Product:

Magnetic steel part

Equipment:

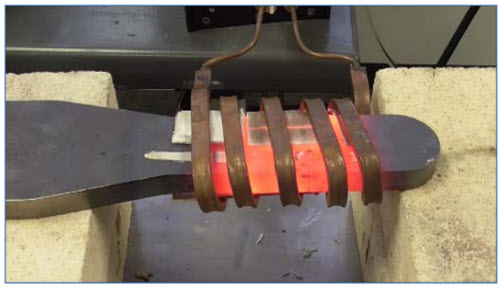

Ambrell EKOHEAT® 15 kW, 50-150 kHz induction heating system equipped with a remote workhead A single position multiple-turn helical coil designed specifically for this application

Materials:

Magnetic steel part

Temperature:

1700 ºF (927 ºC)

Frequency:

125 kHz

Testing:

Temperature indicating paint was applied to the part to easily identify when it achieved temperature, and then the induction power was turned on. It took about three minutes for the part to reach 1700 ºF (927 ºC) at 10 kW and two minutes and twenty seconds with 15 kW for this through-Curie heating application

Benefits:

-

Speed: Induction heated the part to forming temperature more rapidly than a torch

-

Precise, repeatable heating: Induction can target the precise portion of the part that requires heating every time

-

Safety: An open flame creates safety concerns, whereas induction is a comparatively safe heating method

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000