Note: Forging rods of various materials and dimensions

Objective:

To heat rods of various materials and dimensions to temperature for forging with a single coil and induction heating system

End Product:

Rod

Equipment:

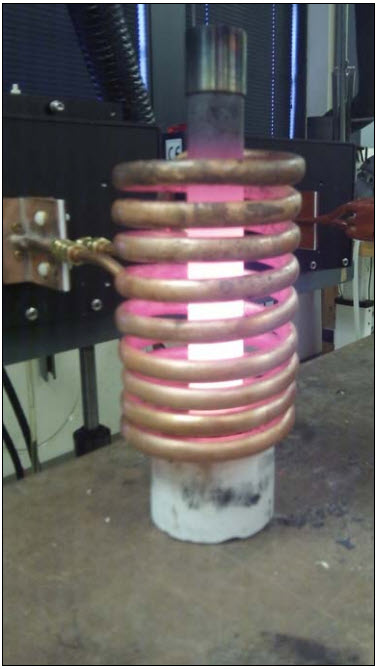

Ambrell EKOHEAT 35 kW 15-45 kHz induction heating system equipped with a remote workhead containing four 6.3 μF capacitors A single position nine-turn helical induction heating coil designed and developed specifically for this application

Materials:

Rods with outside diameters ranging from 0.5” to 1.0” (13 to 25 mm) and lengths ranging from 2.75” to 8.5” (70 to 216 mm) made from steel, stainless steel, Inconel and titanium

Temperature:

1832 ºF (1000 ºC)

Frequency:

38 kHz

Testing:

Each of the rods were placed into the coil and heated. They achieved the targeted temperature in 30-40 seconds. The coil was designed for a 5” (127 mm) heat zone.

Benefits:

-

Speed: The client was using a less powerful competitive system, and consequently, heating the larger rods could take nearly three times as long as this solution

-

Higher throughput: Less heating time means an improved production rate

-

Reliability: The client’s old induction heating system from a competitor wasn’t reliable, and a new system from Ambrell resolves that issue

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000