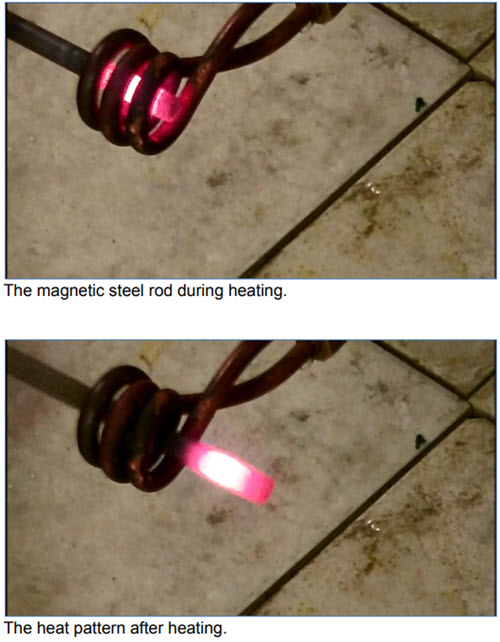

Note: Forging a magnetic steel rod

Objective:

Heating a magnetic steel rod for a hot heading application; the client is replacing a torch

End Product:

Magnetic steel rod

Equipment:

Ambrell EASYHEAT LI 9 kW / 150-400 kHz induction heating system A single position, three turn helical coil

Materials:

Magnetic steel rod (.25”/6.4 mm)

Temperature:

1832 ºF (1000 ºC)

Frequency:

362 kHz

Testing:

Testing determined that the magnetic steel rod heated to required temperature within 1.5 seconds with an EASYHEAT LI induction heating system. The steel rod was positioned so the end was extended slightly beyond the coil. This enables a slightly lower temperature at the end of the rod, creating an ideal heating pattern.

Benefits:

-

Rapid heating: The client had been using a torch, and induction can present some speed advantages

-

Efficiency: Induction is far more efficient than a torch

-

Repeatability: With induction, the client gets the same result every time

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000