Note: Flattening/Bending Steel Tubes

Objective:

To heat steel tube ends for a flattening/bending application; the end user manufactures products in the industrial instrument industry

End Product:

Industrial instruments

Equipment:

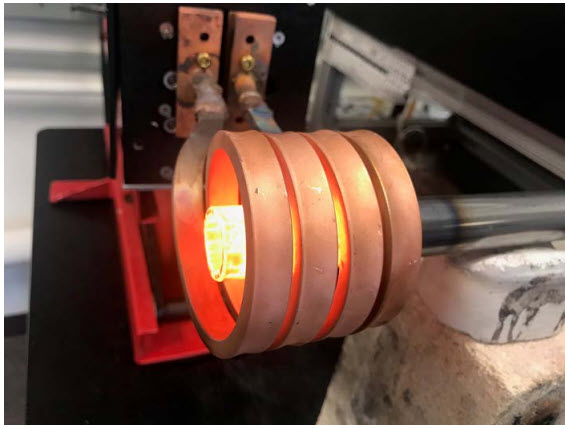

Ambrell EASYHEATTM 8.3 kW, 150-400 kHz induction heating system equipped with a remote workhead A single position, multiple-turn helical coil designed specifically for this application

Materials:

Steel tubes

Temperature:

1600 ºF (871 ºC)

Frequency:

191 kHz

Testing:

First, temperature indicating paint was applied to the part, which dissolves when the part reaches the target temperature. It took less than 20 seconds to heat the provided smaller tube sample to 1600 °F (871 °C) and it took 40 seconds to heat the larger sample tube to temperature. The client was seeing heating times of at least two minutes with an oven, so this is a significant improvement.

Benefits:

-

Speed: Induction heated the tubes to forging temperature much more rapidly than an oven

-

Precise, repeatable heating: Induction can target the precise portion of the part that requires heating every time, presenting another advantage over an oven

-

THE LAB experience: The client was looking at an induction competitor too, but went with Ambrell due to its extensive application experience and reputation for manufacturing quality systems

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000