Note: Induction Melting Glass for Fiber Drawing

Objective:

To heat a metal susceptor vessel to 2200°F within 25 minutes for a fiberglass melting application

End Product:

fiber

Equipment:

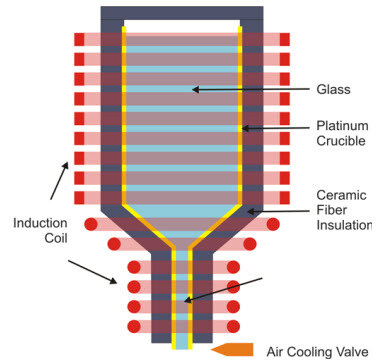

Ambrell 20 kW RF power supply, remote heat station and a specially-designed induction coil.

Materials:

Metal susceptor vessel

Temperature:

2200°F

Frequency:

300 kHz

Testing:

A specially-designed induction coil, shaped to conform to the metal vessel, was used to deliver uniform heat to the vessel. Initial tests were conducted to establish a heating pattern and time-to-temperature. RF power was applied for 22 minutes and the vessel reached a temperature of 2,200°F. An additional 3kW power supply was suggested for use when the glass in the vessel is emptied through the drain tube.

Benefits:

Uniform and repeatable results were achieved with the Ambrell power supply and coil. The vessel can be maintained at 2200°F so that glass can be melted for fiber drawing.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000