Note: Preheating steel rods for forging 1

Objective:

Heat steel rods to 2100 ºF (1149 ºC) while achieving a cycle time of 25 seconds

End Product:

Steel rod

Equipment:

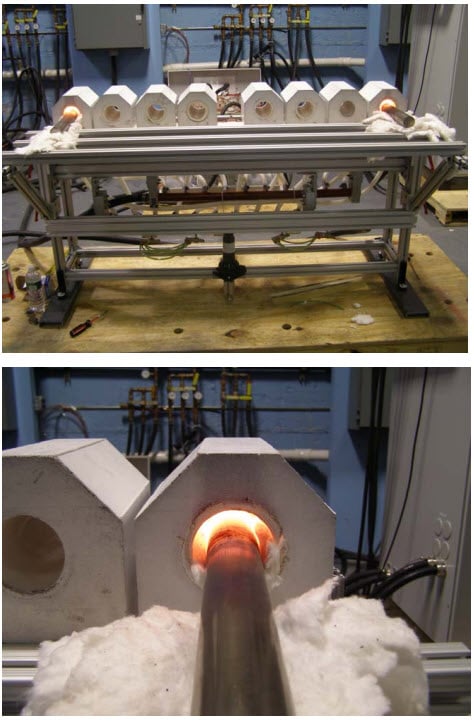

- Ambrell EKOHEAT 375, 250 kW induction heating system, equipped with a remote workhead containing four 40 μF capacitors

- Eight multiple position, multiple turn helical coils designed and developed specifically for this application

- Dual color optical pyrometer

Materials:

Steel rods ranging from 0.75” (19 mm) to 3” (76 mm) in diameter

Temperature:

2100 ºF (1149 ºC)

Frequency:

4 kHz

Testing:

Initially, tests were conducted to determine the optimal way to heat steel rods evenly across the length of the rod. Once the coil design was determined, the process was designed. Eight coils were created, so eight rods could be heated to the desired temperature at the same time. This process achieved the target cycle time of 25 seconds per part.

Benefits:

-

Fast heating: The client targeted an aggressive cycle time, which Ambrell was able to achieve thanks to its process design and the efficiency of induction heating

-

Throughput: Fast heating means greater manufacturing throughput

-

Superior design: The client previously went with Ambrell due to the design of a similar system for smaller rods.

-

Responsiveness: The client was looking for a true partner in an effort to design an optimal, time saving heating process for their application, and they found that in Ambrell.

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000