Note: Fuse thermoplastic catheter tubes

Objective:

Fuse elastomer (TPE) tubes together in two ways, as a butt joint and as a overlap joint.

End Product:

Catheter

Equipment:

Ambrell 1 kW induction heating system, equipped with a remote workhead containing two .33µF capacitors (for a total of .66 µF).

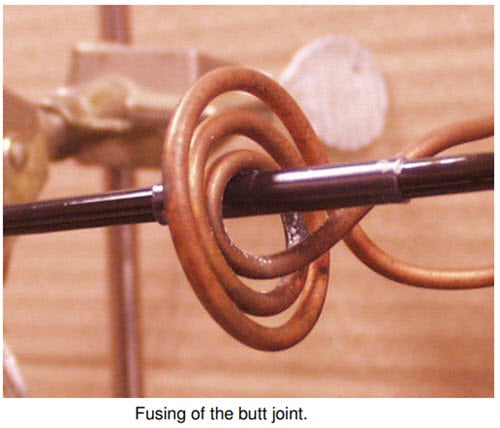

Induction heating coils designed and developed specifically for this application.

Materials:

PeBax tubing 3/16 in (4.76 mm) OD, 1/8 in (3.18 mm) ID and slightly larger

Stainless steel Teflon coated mandrel 1/8 in (3.18 mm) diameter

Temperature:

350 ºF (177 ºC)

Frequency:

352 kHz

Testing:

For the butt joint, two tubes of the same diameter with differing degrees of hardness are used. The tubes are slipped onto the Teflon coated mandrel and a short length of shrink tubing is placed over the tubes. Hot air is blown over the shrink tubing to gently heat it. The assembly is placed in the center of a three-turn pancake coil and heated for 8 seconds.

For the overlap joint, the two tubes have different diameters. The smaller diameter tube is placed over the mandrel first and then the larger diameter tube is slipped over it. A length of shrink tubing is placed over the assembly. Hot air is blown over the shrink tubing to gently heat it. A nine-turn helical coil is used to fuse the complete assembly together.

Benefits:

-

Heating of the mandrel is from the inside out providing a smooth finish on the outside of the assemblies.

-

Precise, repeatable application of heat.

-

Ambient temperature factors do not affect the process

-

No over heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000