Note: Brazing steel coupons, carbide cutters

Objective:

To heat steel coupons and carbide tips/cutters to temperature for brazing and de-brazing; the client was using a torch and is manufacturing an oil industry product

End Product:

Steel coupons

Equipment:

Ambrell EASYHEAT 7.5 kW, 150 to 400 kHz induction heating system equipped with a remote workhead containing two 1.0 uF capacitors for a total of 0.5 uf

A single position, four turn helical induction heating coil designed and developed specifically for this application

Materials:

Steel coupons

Steel cutters

Braze disc

Black brazing flux

Temperature:

1400 ºF (760 ºC)

Frequency:

190 kHz

Testing:

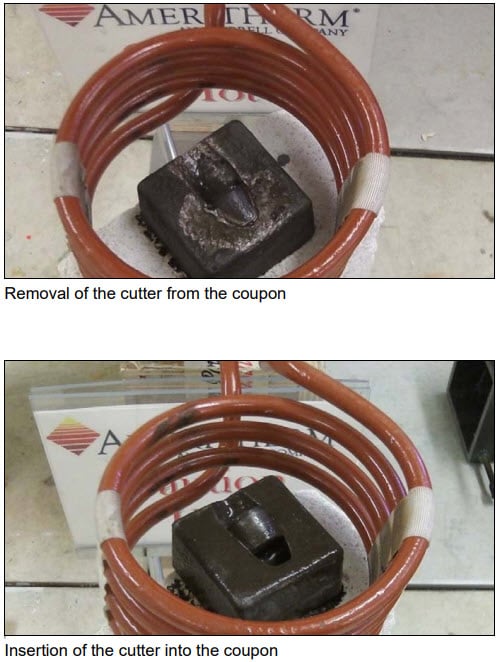

The first coupon that was heated had a 16 mm (0.63”) diameter cutter, so removal of the cutter was the objective. The part was coated in black flux and inserted into the coil. Next, it was heated, and once braze reflowed the cutter was removed from the coupon. The heat cycle time to bring the assembly to temperature was approximately two minutes. The parts were then cooled with water and sandblasted. The next process was to braze a new cutter into the coupon. The cutter was placed in the slot and the assembly was coated with flux. The full assembly was placed into the coil and heated. As the coupon achieved temperature, existing braze on the coupon began to flow and the cutter was slid into place. Then the 16 mm (0.63”) braze disc was stick-fed into

Benefits:

-

Speed: Induction enabled the brazing process to be completed more rapidly than with a torch

-

Safety: There is no open flame with induction, so it’s a safer heating option than other options such as torch heating Efficiency: Induction delivers heat only where it’s required, making it more efficient than torch heating

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000