Note: Brazing carbide tips to a steel cutter

Objective:

To heat a steel and carbide assembly to 1450 ºF for a carbide tip brazing application where the customer needs to repair broken carbide tips on a copper cutter

End Product:

Steel cutter blade

Equipment:

Ambrell EASYHEAT 5kW 150-400 kHz induction heating system equipped with a remote work head containing one 1.0 μF capacitor

A single-turn helical induction heating coil designed and developed specifically for this application

Materials:

Customer supplied steel cutter blade and carbide pieces

Temperature:

1450 ºF (800 ºC)

Frequency:

275 kHz

Testing:

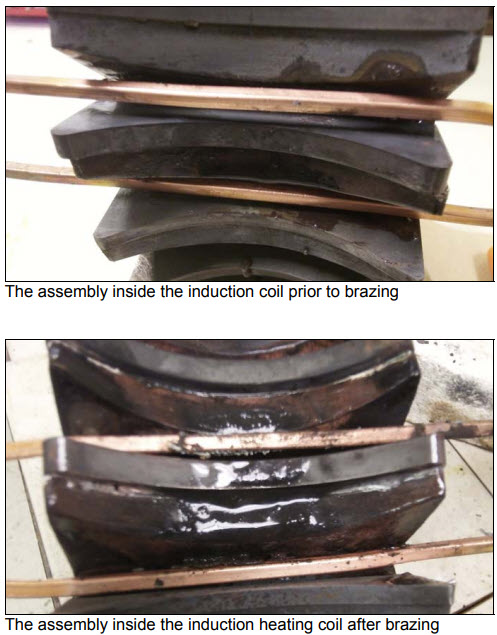

This brazing application requires the application of high intensity heat to the joint area. This is so that thermal conduction of steel and carbide does not sink away heat

delivered via induction. Consequently, a smaller 1/8” (3.175mm) copper tube coil was designed to deliver heat effectively to the joint area.

The cutter was held in a vice and the coil was presented to heat the assembly. A ceramic rod was used to press the carbide tip onto steel cutter during brazing. The heating process was successful.

Benefits:

-

Part quality: The repaired assembly met all quality expectations

-

Speed: While this particular client wasn’t concerned about speed since the system is going to be used for repair and not be part of a production process, induction is faster than methods like torch brazing

-

Safety: Induction is flameless and introduces less heat into the production environment than torch brazing

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000