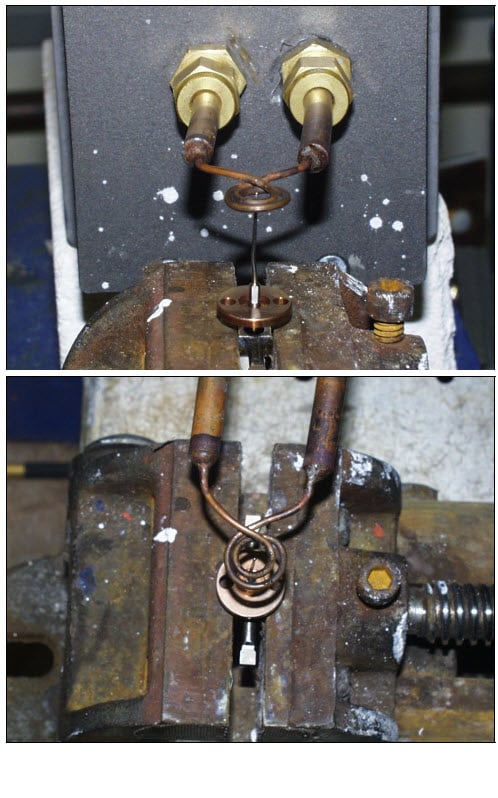

Note: Brazing a carbide ball to a spring

Objective:

To heat a tungsten carbide ball and steel rod that acts as a spring

End Product:

Tungsten carbide ball and steel rod

Equipment:

Ambrell EASYHEAT 0224, 2kW 150-400 kHz induction heating system equipped with a remote heat station containing two 0.33 μF capacitors

A single position, two-turn pancake induction heating coil designed and developed specifically for this application

Materials:

Steel rod (0.025”/0.64mm diameter)

Tungsten carbide ball (0.0468”/1.19mm diameter)

Braze

Black flux

Temperature:

1300 ºF (704 ºC)

Frequency:

313 kHz

Testing:

Initial testing was conducted to optimize power delivered to the part. First, de-brazing an old assembly took place. The part was fluxed and placed into the induction heating coil. The power was turned on and the parts began to heat. A ceramic rod was used to dislodge the ball and the power was turned off. In order to braze a new ball on top of the rod/spring, the ball was fluxed and placed on top of the rod. The power was turned on and the assembly began to heat. The flux transitioned through its clear phase and the power was turned off. With 2kW of power, the parts can be heated to the targeted temperature within five seconds or less.

Benefits:

-

Experience: Ambrell has successfully implemented a similar solution, and that experience made them extremely interested in working with Ambrell

-

Responsiveness: Ambrell’s ability to conduct testing and pass along samples proved helpful to the client

-

Part quality: The end user was impressed with the quality of the part

Visit our Applications Lab to learn more about free applications testing.

1655 Lyell Ave, Rochester, NY 14606 USA | Tel: +1 585 889 9000